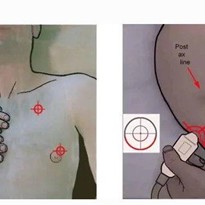

When we say the entire device, we mean the probe shaft and handle, the cable, the plug, the probe holder and controls. Decontamination must consider all parts of a device, as confirmed by published guidance and science:

“The electrical cable and plug socket can similarly become contaminated. Therefore, the whole of the probe – not just the insertion tube – should be carefully cleaned followed by wiping with disinfectant.” HTM 01-06: Decontamination of Flexible Endoscopes. Part C: Operational Management, 3.68

“Other surfaces (controls, keyboards, electrical connectors, etc.) may have sequential contact with an operator’s contaminated gloved hands and the probe.” HIS guidance for the decontamination of intracavity medical devices

“Infection control processes for ultrasound focus on the probe, but we have also shown that probe cords and machine keyboards present significant sources of infection and that this can include potential pathogens.” Potential infection control risks associated with ultrasound equipment – a bacterial perspective. WFUMB (ASUM)

UV and H2O2 -based machines cannot treat the entire device. The dimension and shape of their chambers are designed to minimise the chemical needed to fill the chamber or the light rays needed to flood it, and these enclosures are only large enough to accommodate the probe. The cable and plug which connect the probe to the console will not fit into the machines and their chambers. The holder in which the probe is located on the console is also neglected.

Ultrasound is in a constant state of evolution

Probe shapes and dimensions are ever-changing. If the chambers of machines cannot fit the entire probe in, then it can touch the side of the chamber. A consequence of this would be that the chemical mist or the light ray may not reach every surface of the probe. If an ultrasound manufacturer’s probe simply does not fit the chamber, an alternative high-level disinfection process must be purchased. In this instance, machines are not adaptable and therefore not future-proof.

360° ultrasound decontamination from Tristel

Tristel’s Trio Wipes System enables you to keep up to date with innovations in ultrasound. Utilising proprietary ClO2 chemistry, the system provides decontamination of entire ultrasound devices, no matter their size or shape. The system is mobile, adaptable, validated and complete.

The Tristel Sporicidal Wipe, which represents the high-level disinfection step, is proven effective in only 30 seconds. That is one minute faster than disinfection in a UV machine and 14 times faster than disinfection in an H2O2 mist machine. So, when seconds count, you can save vital time without compromising on efficacy and coverage.

Tristel ultrasound decontamination systems are manually applied. Our competitors often criticise this because we rely on human action. But every manufacturer recognises that wiping works. In fact, they are all 100% reliant on wiping.