Vaccines should never be allowed to remain in a nonfunctioning unit for an extended period of time. Therefore, making preparations in advance to retrieve and/or protect vaccines as quickly as possible during a potentially compromising situation could save your facility costly vaccine loss.

Backup Equipment

No piece of vaccine storage equipment is infallible. At some point, equipment will fail because of a power outage, breakdown, or normal wear and tear.

At a minimum, every facility should have:

- Backup TMDs (Temperature Monitoring Devices)

- Spare batteries

- Flashlights (in case of a power outage)

- Vaccine transport containers and materials

Your facility may also choose to have a backup storage unit so that vaccine may not have to be packed and/or moved to an alternative storage facility if the primary storage equipment fails

Generators and Backup Battery Power Sources

An on-site generator can prevent having to transport vaccine to an alternative storage facility during a power outage. Keep sufficient fuel on hand to continuously run the generator for at least 72 hours.

A backup battery power source can also be used in lieu of a generator. If your facility has a backup battery power source, it should be tested quarterly and serviced annually (check the manufacturer’s guidance for testing procedures and maintenance schedules).

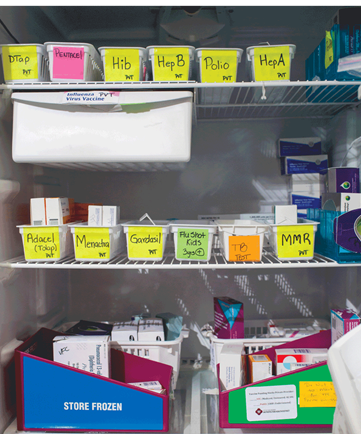

Alternative Vaccine Storage Facility

Even if you have backup equipment or a generator, you should establish a working agreement with at least one alternative storage facility with a backup generator where vaccines can be appropriately stored and monitored in an emergency. Hospitals, long-term care facilities, state depots, the Red Cross, fire stations, packing plants, and commercial pharmacies are some of the facilities that may be able to assist you.

An agreement with an alternative facility should allow you to store vaccines when:

- Severe weather conditions are expected. If there is reasonable cause to believe weather circumstances might impact your facility, implement emergency procedures in advance of the event.

- Equipment fails or power cannot be restored before the storage unit temperature rises above the recommended range.

Always make sure you can have 24-hour access to the alternative facility but if one isn't available, you can use qualified containers and pack-outs* to store vaccines temporarily and safely at your facility. Always place a TMD with the vaccines. Temporary storage containers should remain closed, and vaccines should only be stored for as long as the qualified containers and pack-outs are validated to maintain proper storage temperatures.

Accessing Your Building After Hours

An emergency situation can arise outside of business hours, and having a relationship with your facility’s building manager and/or security staff can be essential to protecting your vaccines. Meet with the manager and/or security personnel regularly and always introduce them to new staff members. Your storage and handling SOPs should have written instructions for accessing your vaccine storage units when the building is closed.

Provide anyone who needs access to vaccine storage units during an emergency with written instructions, a building diagram/map, and locations of:

- Spare batteries

- Flashlights

- Keys

- Locks

- Circuit breakers

- Packing materials

Keep information on after-hours building access and security procedures (including alarm codes) with the SOPs, and also make sure relevant staff members (and building management and security staff, if appropriate) have copies of this information available at home.

Power Outages

During a power outage, never open the storage unit door until power is restored or it is determined that vaccines need to be packed in separate storage containers and/or transported to an alternative storage facility.

Impact of Power Outages on Vaccine Storage

- Portable vaccine refrigerator/freezer units† (recommended)

- Qualified containers and pack-outs

- Hard-sided insulated containers or Styrofoam

- Coolant materials: frozen 16.9- or 8-ounce water bottles that can be conditioned or 4° C to 5° C phase change materials (PCMs)

- Insulating materials such as bubble wrap or corrugated cardboard—enough to form two layers per container

- TMDs for each container - (Temperature Monitoring Devices)

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)