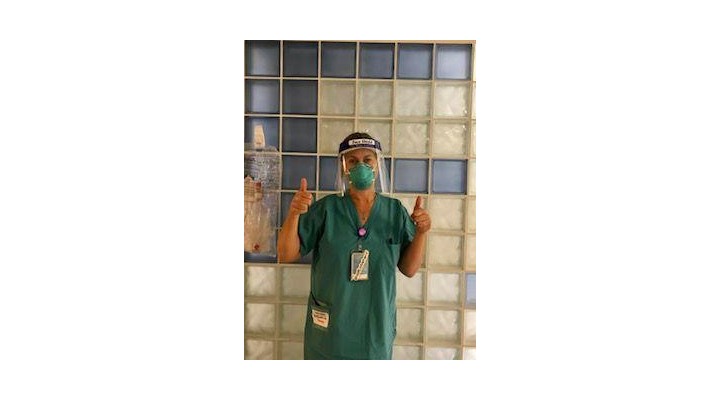

HLP Klearfold has become a very significant producer of single-use face shields, PPE (personal protective equipment) for use by healthcare professionals and for any other essential service providers like food service workers. Since the onset of the COVID-19 crisis, the company has already supplied tens-of-millions of face shields to government and medical agencies around the world, and now Australia.

“We applaud the manufacturing community’s efforts to reallocate resources to produce PPE to help protect our front-line healthcare and other workers,” said HLP Klearfold President, Steve Frazier. “HLP Klearfold leadership in the clear plastic packaging market has made us uniquely qualified to produce face shields. Our production facility is the largest facility of its kind in the world. We have the capacity to make approximately 1 million printed plastic folding cartons per day but, in light of the need for more PPE, we’ve dedicated much of our focus and manufacturing resources to producing face shields, and we are able to manufacture nearly 900,000 per day.”

We repurposed a significant portion of our production capabilities to manufacture low-cost and effective single-use face shields. These face shields are made using the same raw materials, technology, and equipment as used to manufacture the company’s plastic packaging. Our designed Face shield is economical, lightweight, one-size-fits-most, and easily go over glasses and masks. It is a ready-to-wear device with a foam forehead pad and an elastic headband.

The company is vertically integrated, with several custom PET and PP extruders, manufacturing the films required to make plastic face shields, and it has no material supply limitations. The availability of suitable film has become a deterrent to many manufacturers that have attempted to repurpose to produce face shields in response to the COVID-19 increase in demand.

All of the new face shields are Class 1 medical devices for use by healthcare professionals. To assure potential purchasers of the quality and reliability of its face shields, HLP Klearfold has gone the extra steps of securing the relevant certifications for such products. Its face shields have been evaluated by third-parties and have been certified to meet both the United States’ ANSI/ISEA Z87.1-2015 and Europe’s EN 166:2001 eye protection standards for droplets and splash.

The face shields are made from one or more of these materials: PET (polyethylene terephthalate), Frosted PP (polypropylene), open-cell polyurethane foam, and/or knitted polyester elastic

-205x205.jpg)