Then, this article will help to answer your “what is the best ID card printer?”

The answer to this question is relative to your purposes and needs.

-What kind of ID cards do you need?

-Do you have a peak time of the year for printing them?

-How long do your cards need to last?

-Once you start issuing cards, how critical do they become to your process/business?

At PPC, we have highly experienced and trained account managers to guide you through the process of purchasing your plastic card printers. Based on your answers, they will suggest a printer better suited to your printing needs.

Along with these, we also have come across our clients asking about the differences in different printers’ types. This article aims to throw light about two distinctly different printing technology types– Retransfer Printers and Direct-to-Card Printers.

Direct-to-Card Printers

As the name suggests, these printers directly print on the card. They are also called as ‘dye-sublimation printers”, and use ink ribbons and cards to print. The print-heads of these Direct-to-Card printers have little glass pixels, though which the ink flows and gets imprinted on the cards.

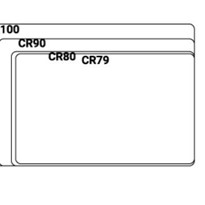

It is easy to identify a card printed through Direct-to-card printer, as it will have a white border on the periphery of the card, where the print heads cannot reach.

Some important features of Direct-to-Card Printing are:

1.Faster printing speeds, good when there will be a peak demand for printing cards.

2.Cost of printing is much lower than retransfer printing (the price of consumables is not expensive).

3.This printer can be used to print on PVC cards and adhesive-backed cards.

Re-Transfer Printers

A technological improvement over the Direct-to-Card Printers, the retransfer printers work on different methodology of printing. More popularly, these are called “reverse transfer”, “high-definition” or even “over-the-edge” printers.

In retransfer printers, an ink ribbon and film are used to print on cards, but not directly. As the name goes, there is re-transference of ink to print the card. Here the printhead doesn’t directly print on the card when it goes in. The ink first gets printed on the backside of a clear film, which then gets ‘transferred’ onto the card by laying on it and heating. The film covers the entire surface of the card, printing end-to-end, without leaving a white border like it does in the designs printed by the Direct-to-Card printer.

Some important features of Retransfer Printing are:

1.Due to re-transference, the printing speeds are lower as compared to Direct-to-Card printers.

2.Cost factor too is a little bit on the higher side, because of the extra consumable.

3.Far better image quality than that of Direct-to-card, complete ‘over-the-edge’ printing is achieved. Additionally, they are more durable.

4.Due to heating process involvement, composite cards that can withstand temperatures are used for this printer, instead of PVC.

5.Retransfer printers are designed to print technology cards and on uneven surfaces.

There are many distinctive advantages to each of these technologies of plastic card printings. Based on your needs and requirements, you can choose them. We invite you to call PPC ID card solutions to talk to our account managers to make an informed choice.